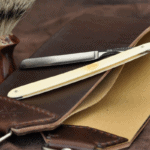

Did you ever thing what compound that could be exist in a leather strop? Is compound necessary on a leather strop? If you are into blade or knives you probably wondering same thing. So let’s find the answer about it!

Is Compound Necessary On A Leather Strop?

So is compound necessary on a leather strop? It depends on what you hope to achieve with the strop. If all you need to do is remove some light burrs from your edge or gently re-align a rolled wire edge, a bare strop can work just fine. In order to continue refining, honing, and/or polishing the bevels, you should use some compound.

The edge must also be ready for stropping for all of this to happen. A strop of any configuration probably won’t help much if the edge isn’t very sharp or not fully apexed, whether it is compound or not. Most of the real work needs to be done on the stones first, and stropping shouldn’t take more than maybe 10-20 passes (or less) to really make the final edge ‘pop’.

Meanwhile, some people believe that honing and polishing an edge with nothing but a bare strop is still possible. It simply does it at a considerably finer grit size than when using another compound. The majority of individuals use Chromiun Oxide (.5mic) as a ‘finishing’ chemical.

Those who want to go even further should utilize a.25mic diamond compound. The natural silicates in a raw leather strop are around.05mic and smaller, which is why it produces such a sharp finishing product.

However, unless you’ve already gotten down to a decent starting point before going to the bare strop, you won’t get the full benefits of that. Yes, a bare strop will clean up some light burrs from your edge, or gently re-align a rolled wire edge, without pulling the edge down first, and will do it extremely nicely, as will denim, your palm, or your shirt sleeve.

However, if you work your way down through the grit sizes and then to the bare leather strop, you will notice a significant difference rapidly. It’ll give you an incredible advantage! In case you need recommendation for best leather strop, we have a list for you.

Recommended Compound

Diamond would always work faster, for a given particle size. Comparing diamond to silica (and there are many types of silica), there’s still a vast difference in hardness, and maybe also a difference in particle/crystal shape, which greatly influences how ‘fast’ or aggressive the particle will cut/abrade/polish.

Diamond & silicon carbide, in particular, are usually known for their more ‘jagged’ shape, sort of like broken glass. Other abrasives might be more ‘blocky’ or roundish in shape, and therefore may not cut as aggressively. So, even if the diamond and silica particles are of relatively similar size, there’d still have to be a big difference in how each works.

However, unless you’ve already gotten down to a decent starting point before going to the bare strop, you won’t get the full benefits of that. Yes, a bare strop will clean up some light burrs from your edge, or gently re-align a rolled wire edge, without pulling the edge down first, and will do it extremely nicely, as will denim, your palm, or your shirt sleeve. However, if you work your way down through the grit sizes and then to the bare leather strop, you will notice a significant difference rapidly. It’ll give you an incredible advantage!

However, unless you’ve already gotten down to a decent starting point before going to the bare strop, you won’t get the full benefits of that. Yes, a bare strop will clean up some light burrs from your edge, or gently re-align a rolled wire edge, without pulling the edge down first, and will do it extremely nicely, as will denim, your palm, or your shirt sleeve. However, if you work your way down through the grit sizes and then to the bare leather strop, you will notice a significant difference rapidly. It’ll give you an incredible advantage!

Paste polishing compounds using aluminum oxide abrasive, like Flitz or Simichrome, also work well. What steels are being stropped determines a lot. Steels with higher abrasion resistance, such as S30V, D2, and others, will respond better to diamond compounds.

Simpler steels, such as 1095 and other basic carbon steels, as well as various mid-range stainless steels, such as 420HC/440-series/AUS-8/etc, respond well to the green compounds. With the exception of the most abrasion-resistant steels, Simichrome works well. I haven’t tried Flitz yet, but many others have, and I believe it will operate similarly to Simichrome.

Use the green compound or a 1 micron diamond most of the time. Those are capable of handling nearly all of my blades. I dabble with others now and then, but I always return to the green and the diamond.

Was this helpful?

Hi there! I’m a food enthusiast and journalist, and I have a real passion for food that goes beyond the kitchen. I love my dream job and I’m lucky enough to be able to share my knowledge with readers of several large media outlets. My specialty is writing engaging food-related content, and I take pride in being able to connect with my audience. I’m known for my creativity in the kitchen, and I’m confident that I can be the perfect guide for anyone looking to take their culinary journey to the next level.

![Preparing [champ chicken sausage] - raw sausages boiling in a pot and cooking in a pan.](https://milkwoodrestaurant.com/wp-content/uploads/2026/02/image-1-4-150x150.jpg)