What Is Honing Compound?

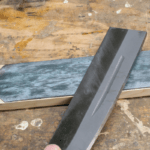

In the last stages of sharpening, the honing compound is extremely fine abrasive. Sometimes these abrasives are loose but are usually held in a medium such as a wax bar, a paste or a spray. In our choice of compounds, the particles vary from 6 microns to approximately 30000 grain grains, equivalent to approx. 2,500 grain of water. Different materials, such as aluminum oxide, chromium oxide and diamond, are used for abrasive particles.

How Do I Use Honing Compound?

In order to be used, the honing compound must be used on a surface. Many surfaces with compounds, one of the best leather stropes, can be used. The surface is applied and the edge is passed over. This is then applied.

Note that the finished abrasive for the sharpening process is sharpening. The abrasive particles are extremely small and polish an existing edge to a mirror, but are not sufficiently aggressive to sharply restore a stubborn edge. Before the compound is used to make the edge sharpened, the finest sharpening stones have been taken.

What Are My Options In Honing Compounds?

We have honing compounds available in wax bars, powders, pastes and sprays.

Wax Bars

Because of their economy and practicality, wax bars are a go-to format for many sharpeners. Simply rub it onto almost any surface, and you’re ready to go. We carry Green Honing Compound, which is the most popular of all our honing compounds. A chromium oxide and aluminum oxide compound in a wax bar, it is fast and effective for polishing to a mirror finish. A 6oz bar goes a long way, providing years of use. I can personally attest that my own has lasted many years and still has plenty left.

Abrasive Powders

Abrasive powders are loose grains which can be sprinkled to polish an edge on a stroke or similar surface. As the grit is not holding a binder on the surface, it may need to be repeatedly applied. We carry a .5 micron aluminum oxide of the abrasive powder.

Pastes

Softer, more spreadable compounds are pastes of honing. Diamond abrasive pastes like DMT Dia-paste and Norton Diamond Paste are available in our selection. The water stones of around 2500, 5000 and 16000 are available in 6, 3 and 1 micron grit. In order to produce a complete polishing set, consider combining them with DiaSpray.

Sprays

Sprayers for achieving sharp edges are clean and easy to use. DiaSpray is carried by DMT, which is classified into a unit. 5 minutes. 5 minutes. It’s a good follow-up to our selection of diamond pastes equivalent to a 30000 grain stone, with little necessary for the results of the mirror finish. Everything you want to do is usually one or two squirts on a stroke.

Honing Guide For Gouges

Flat blades and chisels can sharpen much easier than gouges, just because it is easier to pass through a sharp surface which fits the shape of the cutting edge. In-channel gouges can be made to match the edge with a variety of cylindrical devices, such as leather wrappers. To hone the exterior of a gouge is to resolve the problem of finding the shape of a compound which holds exactly the shape of the coupe. The best way to define that form is through the use of the gouge itself.

Choose a piece of smooth, knotless wood, the sweeter the better. Cut in a channel with the tube to be refined. Cut the channel deep enough to have the whole edge under the wood surface. The channel’s cross section should have the exact form of the edge-on gouge. Then frozen onto the surface of the channel a generous cover of Veritas blade honing. Pressing the gouge into the channel so that the outer surface at and behind the edge bears firmly on the wood, drag it backward along the channel a number of times, until the edge takes on a mirror sheen. If the inner surface has been given a proper honing, you will have a razor-edged gouge, ready to use.

Was this helpful?

Hi there! I’m a food enthusiast and journalist, and I have a real passion for food that goes beyond the kitchen. I love my dream job and I’m lucky enough to be able to share my knowledge with readers of several large media outlets. My specialty is writing engaging food-related content, and I take pride in being able to connect with my audience. I’m known for my creativity in the kitchen, and I’m confident that I can be the perfect guide for anyone looking to take their culinary journey to the next level.