Buffing compounds are used to increase the wheel’s efficiency…

…and to help you accomplish your work quickly…

…with this super guide of buffing and polishing wheels.

They come in all kinds and colours…

…each of which is unique for a different aspect of the buffing, cutting and polishing.

Some are more rude and enable you to remove scratches…

…from different metal surfaces quickly…

…while others are more gentle and designed to give you a lovely and brilliant finish.

It has the contrast between red and tripoli is one big difference that you will notice:

Rouges are typically used to polish and finish…

…while tripoli is used to cut and buff the metal to remove scratches.

But, how do I use buffing compound?

The best way to apply these products is to start from one end of your workpiece…

…and move towards the other end.

…You want to avoid applying too much pressure…

…when buffing because it will cause damage to the material being polished.

If you feel resistance while moving the stick back…

…and forth across the surface, then stop for a moment…

…and let the product dry before continuing.

The more often you repeat this action, the smoother the finished result will be.

Before jump into next section, Let us hear Jade’s story…

I have a set of knives that I use to cut up my food.

As I started culinary school,

my grandfather gave me this set of knives that are so precious to me.

All of them are stainless steel, and they work great,

but they are hard to clean when they are wet or dirty.

At first, I was frustrated by it.

I then discovered a buffering compound

that I could apply with water to prevent rust on the blades.

Rather than just protecting the metal,

I consider coating the entire thing in epoxy resin.

Even after being submerged in liquid, this should provide protection.

However, this may make sharpening more difficult.

Also, I need to apply it carefully to avoid ruining the finish.

Below is a list of our most popular buffer compounds…

…to help you understand the difference and decide which one is right for you.

And we have super review about leather strop for you as well if you are interested.

Let’s jump right in!

Tips for Polishing Knives

If you need help choosing which compounds are right for your job…

…this knife polishing guide will help.

You may find the options overwhelming…

…but keep in mind that polishing is usually a multi-step process…

…to achieve the desired results.

With experience, you will be able to determine…

…how many steps are appropriate for you.

To do the job easily and quickly, we recommend starting with the finest compounds.

In addition to not removing more material than necessary…

…you shouldn’t spend three hours doing a task that takes 15 minutes.

Experimentation is the best way to learn.

Start with a few scraps so you can experiment…

…with the different compounds and how they cut or polish.

Anyway, here’s my best recommendation if you are looking for a great leather strop!

- Leather Strop Double-Sided: for beginners and professionals that like honing to keep woodcarving tools razor sharp. Use both sides of the strop to maintain a needed cutting edge.

- Polishing Compound: included in this kit, so you can start sharpening your knives or other woodcarving tools immediately. The sharpening strop with compound is suitable for all types of knives.

- Sharpening Strop Ergonomic Handle: ashwood shaft allows use of a two-sided strop in a more comfortable way. The handle of the leather strop sharpener is suitable for both professionals and beginners.

- Paddle Strop E-Books Bonus: when buying this professional sharpening strop, youll get eBooks on how to sharpen whittling knife and 5 steps to sharpen a hook knife for any level of skill.

- Honing Strop From Europe: this paddle and compound come from a European manufacturing site so you can be sure that they respond to high standards and requirements of carvers!

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Black Emery Buffing Compound

This compound is filled with emery minerals…

…and gives it high quality cutting so that it is ideal for scratching…

…tiny pitching, placing, painting, antiquing, painting and more from metal surfaces.

You should start with this compound for large work…

…and work that takes a lot of work to remove raw surfaces…

…or deep scratches because it saves time and effort.

It even starts polishing for you…

…usually leaving metal on the surface with a fair shine.

- Coarse cutting compound for stainless steel polish

- Stainless steel polishing compound: used for first stage polishing and cutting stainless steel, steel, iron and other hard metals

- This metal polishing compound work well sith sisal buffing wheels, treated cotton buffing wheels and other hard buffing wheels which used on first stage polishing and cutting

- Size of this black polishing compound: 500g

- Shrink-wrapped

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Keep reading…

Greystar Buffing Compound

Greystar has a very good cut while producing good colors in all metals…

…it is designed for general use.

The medium-grade composition of this compound is fine and consistent in abrasives.

It is ideal to remove firescales quickly and efficiently.

Best used with a more rigid buffing wheel in stainless steel.

- 6PCS polishing buffing compound kit,coarse to fine for all metals

- Kit includes each 1PC 100g polishing compound bar black emery,general green,white,brown tripoli,all purpose blue and red rouge

- Idea for stainless steel,steel,iron,aluminum alloy,brass,bronze,copper,silver,gold etc. polishing and buff

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Brown Tripoli Buffing Compound

This tripoli buffing compound is designed both for buffing and polishing purposes.

The compound can easily be cut off and scratches removed when the finish is smooth.

It is the best ingredient for softer metals such as metal…

…copper, aluminum and various pot metals.

It can also be used safely for stuff like stainless steel or wood surfaces…

…which makes the wood luscious when finished.

- High-quality aluminum polishing compound

- Buffing compound size: 500g

- Used for initial polishing of soft metals, such as aluminum alloy, brass, bronze, copper, silver, gold etc.

- Work well with sisal buffing wheels, stitched cotton buffing wheels, yellow muslin buffing wheels, and cutting airway buffing wheels

- Shrink-wrap

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

White Rouge Buffing Compound

White red buffing compounds are an excellent compound…

…especially for harder metals such as chromium and nickel-plated materials.

It gives your buffer wheel a light cutting edge…

…and brightens those harder metals when finished.

It can also be used as a blizzard compound for the final finishing…

…of harder metals or for lighter cuts on smooth metals.

- 1-Pound bar

- White color

- Package Dimensions : 6.25 L x 1.75 W x 1.5 H

- Made in Ch

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Go on…

Water Soluble Red Rouge Buffing Compound

- RED ROUGE POLISHING COMPOUND - The Enkay Red Rouge bar polishing compound is used for buffing soft, fine, and precious metals to bring out the maximum luster finish with phenomenal results.

- POLISHES YOUR JEWELRY TO MIRROR-LIKE FINISHES - This jewelers rouge is perfect for polishing your jewelry that will make them look like brand new after working on them. This polishing compound is perfect for gold, silver, platinum, and brass.

- WORKS WITH ALL KINDS OF JEWELRY AND METAL - Turn your old and rusty jewelry and metals into something wonderful. This jewelers rouge works perfectly on gold necklaces, bracelets, earrings, rings, anklets, and other types of jewelry. You can also polish your silverware, knife, stainless steel, chain, and watches.

- 4 OZ - The Enkay Red jewelers rouge is available in 4 oz and made in the U.S.A. This polishing compound measures at 4 oz. or 5 x 1 x 1 1/2.

- MUST HAVE FOR JEWELRY AND WATCHES COLLECTION - Keep your jewelry and metals look fresh and polished as this Enkay red rouge is a must-have for collectors, hobbyists, and for the everyday people. This red rouge can also polish and buff scratches out of metal and glass surfac

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

It works as regular red red rouge will…

…it gives the metals you use with an excellent quality polished finish…

…and it is particularly useful for gold, money and other precious metals.

It is also water soluble, making it much easier to break down…

…and clean away with the help of water…

…which makes this compound unique from the typical red Rosses.

Red Rouge/Jeweler’s Rouge Buffing Compound

The red blue is commonly termed a red gem…

…as it is widely used by jewelers and provides gold…

…silver and many other precious metal because of the unrivaled level…

…of high quality polishing.

This red will reveal the true colors of every metal in a very short time…

…and shine like a new one.

It can also be used safely on pieces with small plating layers.

- RED ROUGE POLISHING COMPOUND - The Enkay Red Rouge bar polishing compound is used for buffing soft, fine, and precious metals to bring out the maximum luster finish with phenomenal results.

- POLISHES YOUR JEWELRY TO MIRROR-LIKE FINISHES - This jewelers rouge is perfect for polishing your jewelry that will make them look like brand new after working on them. This polishing compound is perfect for gold, silver, platinum, and brass.

- WORKS WITH ALL KINDS OF JEWELRY AND METAL - Turn your old and rusty jewelry and metals into something wonderful. This jewelers rouge works perfectly on gold necklaces, bracelets, earrings, rings, anklets, and other types of jewelry. You can also polish your silverware, knife, stainless steel, chain, and watches.

- 4 OZ - The Enkay Red jewelers rouge is available in 4 oz and made in the U.S.A. This polishing compound measures at 4 oz. or 5 x 1 x 1 1/2.

- MUST HAVE FOR JEWELRY AND WATCHES COLLECTION - Keep your jewelry and metals look fresh and polished as this Enkay red rouge is a must-have for collectors, hobbyists, and for the everyday people. This red rouge can also polish and buff scratches out of metal and glass surfac

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

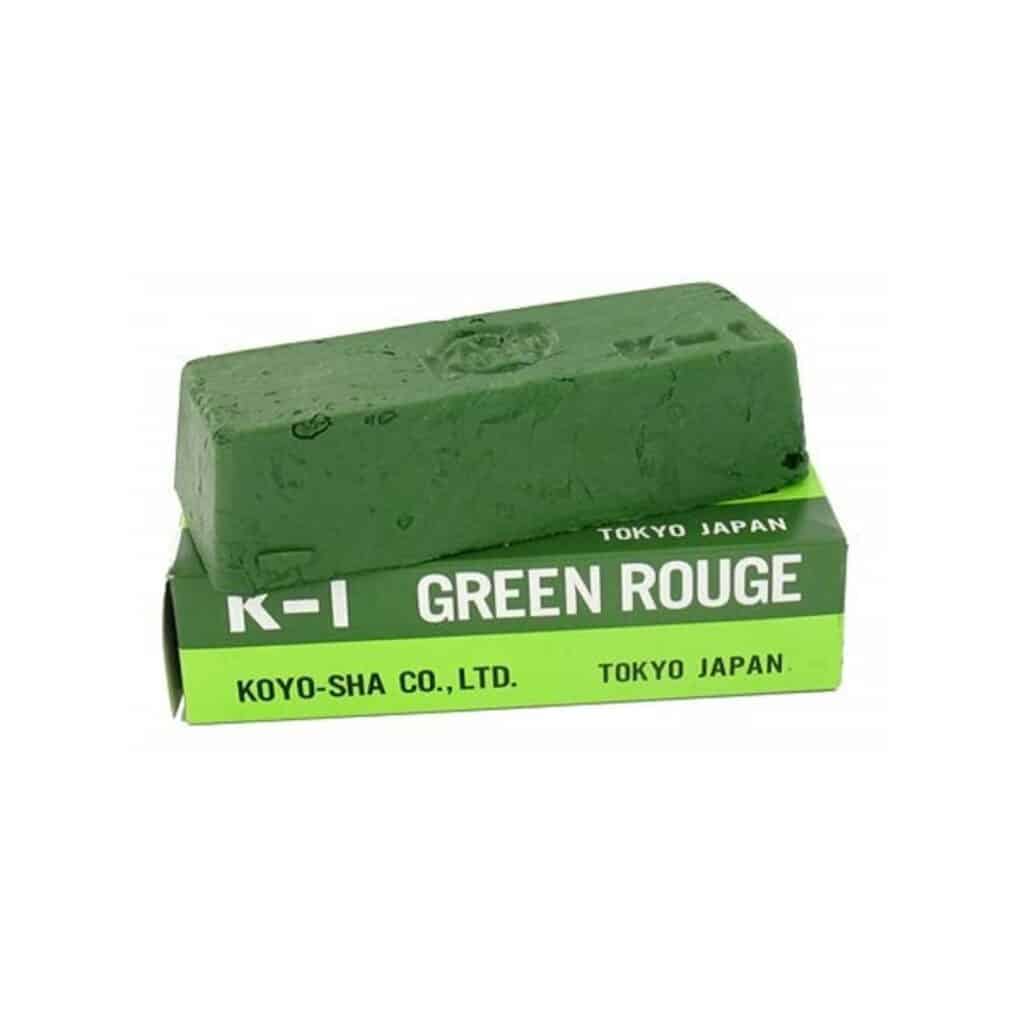

Green Rouge Buffing Compound

This green red is a buffing compound…

…which has a high luster finish on soft and hard metals.

While it can be used in hard and soft metals easily and safely…

…it is best used with things such as chrome, stainless steel and platinum…

…which are the reason why this compound is sometimes referred to as Stainless Steel.

The finishing will be brighter and better than a white red compound.

- Green - Extra fine

- For most metals

- 1 pound bar

- 400 - 600 g

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

If you’re concerned about knife care, here’s something else you may want to know…

Quick Guide to Strop

The strop is used after the finest stone for the final stage of sharpening.

Strops are used to polish edges…

…and remove burrs left behind by sharpening stones.

“A strap; more specifically a piece of leather or a substitute (notably canvas), or strip of wood covered with a suitable material, for honing a razor, in this sense also called razor strop.”

A definition of strop from Wiktionary.

Strops are most often made of leather…

…although other materials may also be used.

Suede and smooth leathers, technically known…

…as flesh side and grain side, are both used.

The base can be rigid, like a leather on wood paddle strop…

…or flexible, like a leather and linen razor strop.

Is A Strop Really Necessary?

The answer is yes!

A knife without a strop would have a rough edge…

…that could cause injury if handled improperly.

In light of how much time and effort went into creating this tool…

…it makes sense as well.

It would be a shame to throw out all those hours…

…spent creating such a useful piece of equipment…

…just because you didn’t know what to do with it.

A good quality strop provides the following benefits:

- Sharpens knives more quickly

- Extends the life of blades

- Maintains a sharper edge throughout the life of the blade

- Improves safety when handling knives

- Keeps blades clean

- Reduces friction between the blade and handle

- Enhances control during slicing and chopping

- Prevents nicks and cuts

- Improves grip

- Provides a smoother finish

- Prevents scratches on the handles

- Maintains a clean appearance

- Prevents rust staining

- Prevents corrosion

- Removes oxidation

- Good for honing compounds

- Can be used with a variety of blades

- Can be easily stored

- Lightweight and easy to transport

- Easy to track

- Less expensive than buying new blades each month

Hey, you might also need this!

- 1.Size:45*5cm/18*2. Material: Cow Leather.

- 2.Used for final sharpening and smoothing after honing razors.Suitable for straight razors, sharpen knives and chisels.

- 3.The razor sharpening strap is made with best quality cowhide leather which allows for smoother shaving blades.

- 4.The razor sharpening straps are finely balanced to allow for an easy sharpening experience. The strop has a handle at the bottom and swivel hanging tab on the top end for ease use.

- 5.Package Included:1 x Razor Sharpening strop strap On

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

So, that’s it!

Sum Up!

There are many different types of buffing compounds…

…that you may choose from depending upon…

…what type of material you wish to polish.

The best way to determine which product would suit your needs…

…is by trying them yourself.

Conclusion

Hopefully this guide on buffing compounds…

…will help you find the right one for you.

We’d love to know what you thought of this article…

…so, please let us know in the comments section below!

Was this helpful?

Hi there! I’m a food enthusiast and journalist, and I have a real passion for food that goes beyond the kitchen. I love my dream job and I’m lucky enough to be able to share my knowledge with readers of several large media outlets. My specialty is writing engaging food-related content, and I take pride in being able to connect with my audience. I’m known for my creativity in the kitchen, and I’m confident that I can be the perfect guide for anyone looking to take their culinary journey to the next level.