Buffing Compound Leather Strop Tips

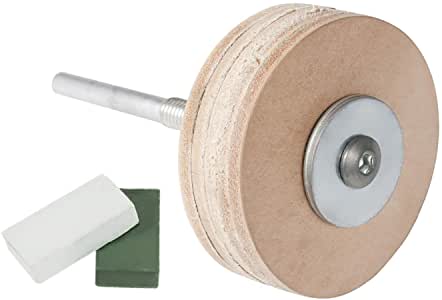

- 1-Pound bar

- White color

- Package Dimensions : 6.25 L x 1.75 W x 1.5 H

- Made in China

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Buffing compound leather strop are used …

…to increase the efficiency of the wheel and can quickly complete your work…

…with this superb buffing compound leather strop and polishing guide.

They come in every type of colour…

Each is unique in terms of a different buffing…

…cutting and polishing aspect.

Some of these are harder and allow you to remove scratches…

…from various metal surfaces rapidly…

…while others are softer and designed…

…to provide you with the finishing touches.

The fact is…

It has the contrast between red and tripoli…

…which you will notice is one big difference.

Red is usually used for polishing and finishing…

…whereas tripoli is used to cut and tighten the metal to remove scratches.

Below is the list of our most popular buffer compounds…

…which helps you to figure out what differences are right for you.

And if you’re interested, we also have a great review of Leather strop for you….

Before we begin to list the tips below…

..this is the best review that you need to know…

..for those who want to learn about Leather Strop!

Now let’s hear Brian’s experience…

I’ve only recently begun collecting knives and learning how to care for them…

I’m not sure what color buffing compound leather strops are commonly used..

I have no experience with this, but as I’m sitting at home hand sanding..

..and trying to put a great glossy layer of poly on some Birdseye…

…he took a bare wood knife handle, threw it on the buffer for 5 seconds…

..and it looks beautiful!

Buffing compounds are an abrasive compound composed of polishing powder blended to form a cake or bar with waxes and fats. They are used to smooth metals in many industries to give a clean and polished finish and improve the polishing and buffing wheel’s effectiveness.

benchmarkabrasive.com

Kee reading…

Applying Compound Small and Often

How know your buffer or polishing wheel the amount of compound?

There is no set amount of stone, but the secret is…

…that small amounts of compounds are often used.

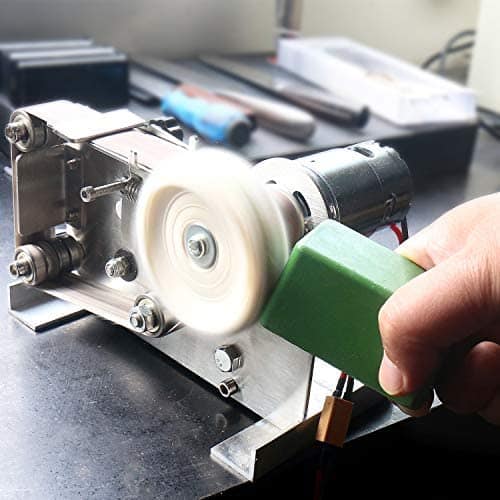

Put your compound on your wheel for about a second…

…or two and then polish it again.

The best way to use the buffing compound leather strop is…

…to add t to the wheel before you try to polish anything.

The part you need to polish helps you to work the compound..

…deeper in your wheel while polishing, so that you get much better…

….faster results while maintaining the compound.

Your Wheel to Clean Up

The best way to clean your Buffer wheel is by a wheel rake with its jagged blade…

Get your blade running, then get the blade side of your rake to the buffer….

Cut the rake softly back and forth on the side…

…of the buffer wheel until it looks fluffy again.

When frequently done, the metal part, which is trapped in the wheel…

…is deleted to prevent further fragile elements from scraping…

…the next time you begin to polish.

The residue can be cut and cleaned with a hot water solution…

…with a number of drops of ammonia in order…

…to make the cleaning more comprehensive.

This process can be done quicker and ultrasonic waves…

…can shake out the loosening grain and waste from the buffer wheel…

…when it is placed in an ultrasonic cleaner.

However, you must allow the wheel to dry completely…

…before using it again to prevent it from being used for a long time.

One Compound and One Wheel

- 1-Pound bar

- White color

- Package Dimensions : 6.25 L x 1.75 W x 1.5 H

- Made in China

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Pack of 20 Pieces of Rotary tool accessories, felt-tipped

- The diameter of whole felts shank is 1/8(3mm)

- With 10 cylinder shaped grinding heads, 10 bullet shaped, different sizes of heads

- Make polished goods clean and bright, best used for various mould, glass, medical equipment, metal, and many more

- Ideal for the rotary grinding and polishing t

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

No need to lay or mix different compounds as much as possible…

…since an unusual abrasive surface mix can be achieved…

…that can harm any advantage you hope to obtain…

…by mixing a thinner or more gross compound.

The deposits of metal left by the preceding polishing wheel…

…also vary according to the coarseness of the compound…

…and can damage components requiring a finer polishing agent.

If you must apply an ingredient to the old wheel, you can do several things…

..first, clean the wheel as described earlier or wear several ingredients wisely…

..if you are not free to completely clean the wheel.

Use a compound that is less complicated than the latter used on the wheel…

…only if compounds are doubled on the used wheel.

Do not use the final polishing or coloring on a rough cutting or buffer…

…but it can damage the part you want to finish with rough…

…remaining particles in the fibre.

Another good alternative to avoid this whole problem is…

…to start with the application of a one-step polishing material like…

…Fabulustre that allows you to polish and buff a variety of metals…

…using only one compound. All possible hazards from changing grains…

…and monitoring, which wheel is used for every compound, are eliminated.

Buffing vs Polishing vs Cut Buffing vs Color Buffing

- DEFECT REMOVAL: Great for removing scratches, defects, acid rain and severe swirls/holograms

- ULTRA-FAST COMPOUNDING: Ultra-fast cutting removes 1200 grit or finer sanding marks

- SUPERIOR FINISH: Exclusive super micro-abrasive technology leaves best-in-class finish

- CLEAR COAT SAFE: Safe and effective on all glossy paint finishes including clear coats

- VERSATILE USE: Formulated for use by hand, dual action polisher or rotary buffer, and is body shop safe. Also available in 8 oz and 1 gallon si

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- ✔ FIRST CHOICE - The abrasive buffing polishing wheel is a durable, small and efficient polishing tool. Provides a smooth, uniform finish and compliance for irregular surfaces.

- ✔ 4 COLOR - 4 Kinds of grit Brown (P120),Green(P180),Red(P320) and Black(P400) to meet your various polishing requirements. Shank Diameter: 3mm / 0.12in, Brush Diameter: 25mm / 0.98in.

- ✔ 40 PACK - 40 Pcs Buffing Polishing Wheels , Brown, Green, Red and Black each 10 Pcs.

- ✔ EASY TO USE - The nylon polishing brush head kit-small polishing wheel included 1/8 (3mm) shank allows operators to attach the assembly quickly and easily to common Rotary Tools.

- ✔FACTORY OUTLET- Factory mass standard production, Guaranteed quali

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

All of these procedures help you achieve the smoothest and brightest results.

Polishing is the process of smoothing a surface with a coarse abrasive…

…similar to sanding a piece of wood with fine and finer sandpapers.

After polishing, buffing is a less harsh stage in which looser…

…and finer abrasives are used to further smooth a surface…

…in order to get a brighter sheen or a mirror finish.

Cut buffing and color buffing are normally accomplished in 1-3 steps…

The first stage in buffing a surface is cut buffing….

To remove any scratches, buff with a coarser buffing compound leather strop…

such as black emery or brown Tripoli.

Some surfaces may appear to be sufficiently buffed…

..at this point and require no more color buffing.

The final step in achieving optimum shine on a surface is color buffing….

The “jeweler’s rouge” color compounds (green and blue)…

..have the finest abrasive materials and can offer the ultimate shine..

..and mirror finish on most metals, woods, stones, and plastics.

Let’s move on…

How do you use Buffing Compound Leather Strop Sticks/Bars?

- PROFESSIONAL CHOICE: 23.5 in length and 2.5 wide, leather razor strop is useful for sharpening straight razors, helping them maintain a honed edge for a close, smooth shaves

- HIGH QUALITY: Made of cow-hide leather, one side of the straight razor strop is made of leather and other made of fine black leather for both sharpening and for polishing to a gleaming shine; comes in a plastic sleeve for protection

- STAINLESS STEEL CLAMP: Barbers strop is joined by the metal-reinforced handle with a swivel clip to hang from a hook or other location; a rounded portion at the bottom serves as a handle so you can pull the strop taut for sharpening

- NOT JUST FOR RAZORS: Shaving strop is also suitable for sharpening kitchen cutlery, filet knives and bait knives so they continue to cut easily and smoothly

- 100% Satisfaction Money Back Guaranteed: We devote ourselves to provide the best customer service and bring the best shopping experience to every customer; If you are not satisfied with our GBS strop, please contact us and we will find a solut

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Once you have sanded down the metal surface with an ultrafine sandpaper…

..a buffing compound bar can give the metal an incredibly shiny and smooth finish.

Based on the project at hand, the tools you are using…

…and your personal preferences…

…there are many ways to apply the abrasives from the compound bar.

The most common buffing wheels used with polishing bars are sisal buffs…

..buffing drums, polishing discs/flap discs, and airway buffing wheels.

Spin the wheel on your power tool and gently press the compound…

…into the edge of the spinning polishing wheel.

Only a small amount of the compound should transfer to the wheel…

Buffing compound leather strop bars should be applied…

…to your polishing wheels in a little and often manner.

You should also change the wheel for each compound…

..to prevent a mixture of abrasives from building up from prior buffing rounds.

Learn The Difference

- What You Will Get - 1pcs mushroom shaped wheel; 1pcs cone shaped wheel; 1pcs column shaped wheels; 3pcs T-shaped polishing pad with different sizes, 5pcs rouge buffing compound, along with a 1/4 metal shank.

- High-Quality Materials - Made of 100% high grade white flannelette cotton cloth material, excellent polishing effect and extremely durable.

- Non-Slip - These buffing wheel has 1/4 hex shaft, can prevent buffing wheel slip during work.

- Polishing Rouge Compound - These Compounds are color coded for easy identification in a scale from coarse to fine. It can emit black cold light after polishing, and the brightness reaches the mirror level. It contains high anti-rus

- Multiple Function - Suitable for surface grinding and polishing of metal, jewellery, hardware, stainless steel, aluminum products, wood, plastic, ceramics, glass and watch

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Grinding – the first step in shaping the metal edge, which can be done with a standard grinding wheel, a diamond whetstone, a manmade or natural stone such an India (manmade), a water stone (manmade), or an Arkansas (natural), or sheets of 280-320-400 grit wet/dry carbide paper on a sheet of glass. Any of these ways will quickly lower the edge, cutting and eliminating any extraneous metal. Other grinding methods include belt sanders, depending on the instruments available and the time allotted by the owner. Honing with a finer grit is the next phase.

- Honing – removing metal faster than buffing with a motorized wheel, usually a hard surface with a coarser* abrasive. This leaves a sharp edge that needs to be stroped or buffed. The term “courser” is misleading because the honing surface still has a very fine grain, and the goal is to smooth the edge rather than remove a lot of metal. On glass, a finer stone, diamond stone, or finer grit carbide paper can also be used.

- Buffing – done with a motorized wheel, using anything from a soft cloth to a hard felt or leather wheel, usually with some kind of magical stuff on it that is nothing more than a very fine metal cutting agent and a fancy colored binder that is usually wax or a similar base to hold the cutting agent on the wheel.

- Stropping – Similar to buffing, but done by hand, dragging a sharp edge along a surface, such as leather, and utilizing the above-mentioned magical substance. The edge is pulled with the sharp edge trailing, removing very small amounts of metal and lowering the edge from a very fine but unpolished edge to a polished and shining edge.

Presents you our top recommendation for leather strop and knife sharpener!

- 1.Size:45*5cm/18*2. Material: Cow Leather.

- 2.Used for final sharpening and smoothing after honing razors.Suitable for straight razors, sharpen knives and chisels.

- 3.The razor sharpening strap is made with best quality cowhide leather which allows for smoother shaving blades.

- 4.The razor sharpening straps are finely balanced to allow for an easy sharpening experience. The strop has a handle at the bottom and swivel hanging tab on the top end for ease use.

- 5.Package Included:1 x Razor Sharpening strop strap Only.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- 3-Step Knife Sharpener: With our incredible 3-slot system, we’re revolutionizing the art of knife sharpening! The 1st diamond sharpening rod repairs and straightens damaged blades before the 2nd slot sharpens to restore its V-shape. Finally, the 3rd slot fine tunes for a clean polish.

- Easy to Use: Whether you’re right or left-handed, the ergonomic handle allows you to restore your cooking knives in a matter of seconds! Simply place the blade in each of the slots and gently pull the knife through a few times for fast, effective sharpening.

- Cut-Resistant Glove Included: At Kitchellence, we put the safety of our customers above all else. Designed with a non-slip base, our kitchen knife sharpener offers comfortable control while you work. We’re even including a cut-resistant glove for added safety!

- Premium Quality: With our professional knife sharpener kit, you don’t have to be a chef to cook like one! Crafted from solid ABS plastic, it’s strong, durable and designed to last a lifetime. Made with high quality materials, knives will look and work like new.

- Shop Risk Free: We’re so confident that you’ll love our knife sharpening kit, we’re backing each order with our unconditional money back guarantee! If you are not completely satisfied, simply return the product within 30 days and we’ll refund your purcha

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- ✅ Superior Bundle: Your complete knife sharpening kit comes with double-sided (#1000/ #6000) premium quality whetstone, bamboo base for holding the stone, knife sharpening angle guide, a simple instruction manual & detailed ebook with lots of Tips & Tricks which will appeal at every skill level

- ✅ Multipurpose Use: Our professional-grade knife sharpener stone is highly durable & long-lasting. This whetstone sharpener can sharp any blade out there, be it any kitchen knife set, chef knife, steak knife, sontoku knife, paring knife, sushi knife, cleaver knife, kitchen knives, Japanese knife, butcher knife, paring knife, BBQ knife, Hunting Knife, Pocket Knife, Scissor, Chisel, Blade, Straight Razor & it can even sharp an axe.

- ✅ Safety: We understand the importance of safety when dealing with sharpening tools, your purchase comes with a Silicone base for holding the stone inside Non-Slip Bamboo base, this setup will ensure the stone is Fixed In One Place while sharpening. And knife sharpening angle guide allows you to maintain the Correct Angle and safely apply consistent pressure while sharpening the blade

- ✅ Easy To Use: Our sharpening Waterstone kit is extremely User Friendly & easy to assemble. Knife sharpener stone uses Water for sharpening, so no need of expensive sharpening/honing oils and No Mess while sharpening & it can be easily cleaned using water

- ✅ Premium Quality: Not all sharpening stones are created equal. We only import & source premium quality material for the manufacturing of our Whetstone which will provide superior cutting performance. No Compromise on quality. Get this simple yet unparalleled tool, used by everyone from stay at home moms to various profession

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

To Sum It Up

Before starting the restoration process…

…assess the extent of the damage if you are willing to do this yourself.

When using the more buffing compound leather strop …

…be careful not to further damage the paintwork.

Test the product on a small area before proceeding with the restoration process…

Conclusion

There are some great details I have shared in this article…

…about buffing compound leather strop.

I hope this article was useful..

..and that I have brought a little bit of clarity…

..to your understanding of buffing compound leather strop.

Thanks for sticking around!

If you have more question about buffing compound leather strop…

..feel free to contact us!

Was this helpful?

Hi there! I’m a food enthusiast and journalist, and I have a real passion for food that goes beyond the kitchen. I love my dream job and I’m lucky enough to be able to share my knowledge with readers of several large media outlets. My specialty is writing engaging food-related content, and I take pride in being able to connect with my audience. I’m known for my creativity in the kitchen, and I’m confident that I can be the perfect guide for anyone looking to take their culinary journey to the next level.